China Track Mechanical Parts Industry Rising

The continuous track mechanical parts sector in China represents a mature and technologically advanced industry that serves as the backbone for heavy machinery operations across multiple fields. This specialized segment has developed considerable technical sophistication through decades of manufacturing refinement and innovation, positioning Chinese manufacturers as significant contributors to the global supply chain for these essential components.

What Are the Key Components and Characteristics of Mechanical Parts?

At the core of continuous track systems are several vital mechanical parts that work in concert to deliver reliable performance under demanding conditions. Track links, typically manufactured from alloy steels, form the fundamental structure of the track chain, with production volumes estimated to reach millions of units annually to meet domestic and international demand. These components undergo specialized heat treatment processes to achieve surface hardness ratings between 55-60 HRC, significantly enhancing their resistance to abrasive wear. Track shoes, which attach to the links, are engineered in various configurations including single, double, and triple-bar designs to provide ideal traction across diverse terrains from loose soil to rocky surfaces. The supporting components—rollers, idlers, and sprockets—work together to distribute operational loads and transfer power efficiently. These elements are constructed to withstand substantial impact forces while maintaining precise dimensional stability, with some roller designs capable of supporting loads exceeding several tons per wheel.

Where Are Mechanical Parts Typically Applied?

China-manufactured continuous track components find extensive application across multiple machinery categories that require enhanced ground contact and mobility. Construction machinery represents the primary application sector, with crawler excavators utilizing these systems to achieve stable working platforms across challenging job sites. Industry analysis suggests that approximately 70% of mid-to-large excavator models incorporate continuous track systems, with Chinese suppliers providing a substantial portion of replacement components for this segment. Agricultural machinery constitutes another significant market, particularly for combine harvesters and track-based tractors operating in soft field conditions where rubber-tracked variants help reduce soil compaction. Specialized applications continue to emerge within the mining sector, where reinforced track systems support heavy-duty haulage equipment operating in bad extraction environments, demonstrating the adaptability and durability of these mechanical solutions.

What Are the Evolutionary Trends in the Development of Mechanical Parts?

The continuous track mechanical parts industry in China is undergoing a significant transformation driven by three key technological trends. Intelligent systems are being integrated into track monitoring, with sensors and data collection modules now embedded in approximately 30% of newly manufactured premium components, enabling real-time performance tracking and predictive maintenance. Lightweight initiatives are gaining momentum through the adoption of advanced high-strength steels and alloy compositions, achieving weight reductions of 15-20% while maintaining structural integrity and load-bearing capacity. Safety enhancements represent another critical development focus, with improved manufacturing techniques yielding components that demonstrate predominant failure resistance under stress testing conditions. These coordinated advances across intelligent systems, material science, and safety engineering are collectively elevating the performance standards and technological sophistication of China's continuous track mechanical parts sector, positioning it for continued advancement in global markets.

Looking ahead, China's continuous track mechanical parts sector is strategically positioned to maintain its significant role in global supply chains. The convergence of intelligent monitoring capabilities, advanced lightweight materials, and enhanced safety features creates a compelling value proposition for international customers. With steady investment in research and development, coupled with extensive manufacturing experience, Chinese manufacturers are well-equipped to meet the evolving demands of global construction, agricultural, and mining sectors. The industry's commitment to technological advancement and quality improvement suggests a promising trajectory for these essential components in international markets, potentially expanding their application to new areas of heavy machinery and specialized equipment in the coming years.

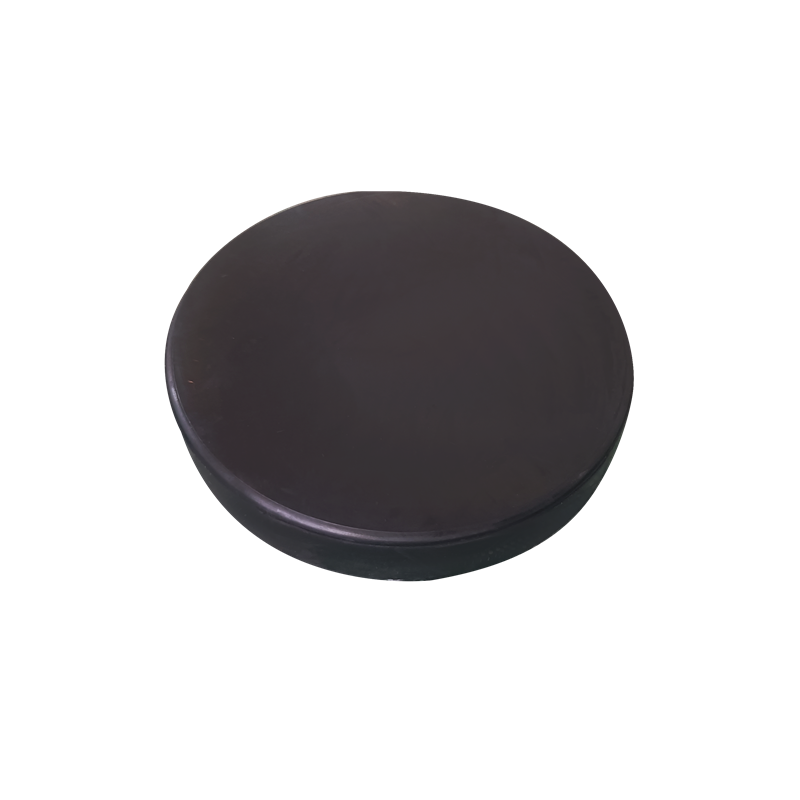

LINHAI HAISDER MACHINERY CO., LTD offers specialized protective covers designed specifically for their rugged terrain vehicles and machinery. These protective solutions combine durable materials with precision engineering to ensure ideal equipment protection in demanding environments

浙ICP备2022029871号

浙ICP备2022029871号