Lawn Mower Walking Systems Enhance Professional Performance

In the world of professional turf management and demanding residential lawns, the lawn mower walking system remains a critical and actively evolving component. Far from a simple mechanical necessity, the design and integration of this system directly impact operator efficiency, business profitability, and the quality of the final cut. Today's developments in the lawn mower walking system focus on a sophisticated balance between human factors, operational economics, and precise application matching.

How Does Ergonomics Redefine Operator Interaction?

The ergonomic design of a lawn mower walking system has become a primary engineering focus to combat operator fatigue and reduce injury risk. Modern systems increasingly utilize a hydrostatic or electric drive, providing smooth, single-lever control over both speed and direction without the physical strain of operating a mechanical clutch. This allows operators to walk at a comfortable, consistent pace for extended periods. The layout of controls is strategically planned to keep hands in a natural position, small repetitive reaching and twisting. Furthermore, systems now incorporate features like cruise control and strategically placed anti-vibration damping to lessen the physical toll of a full workday. Research into operator efficiency suggests that well-designed walking systems can contribute to measurable gains in productivity over traditional, less refined designs by reducing required effort and allowing focus to remain on mowing precision rather than physical exertion.

Why Is This System a Pillar of Commercial Viability?

For commercial landscaping businesses, the lawn mower walking system is a central factor in operational cost and output. The durability and low maintenance requirements of the drive system are paramount, as commercial machines can accumulate hundreds of hours of use per season. A reliable lawn mower walking system lesss downtime and repair expenses, directly protecting profitability. Commercial-grade walking systems are built with heavier-duty transmissions, axles, and wheels to withstand constant use on varied terrain. Additionally, the cutting width and efficient power transfer of the walking system determine the area that can be covered in a given time. Businesses often calculate a cost-per-acre metric that includes fuel consumption and labor time, making an efficient, reliable lawn mower walking system a key contributor to a favorable bottom line and a strong return on equipment investment over many years of service.

How Does Scenario Adaptation Dictate System Design?

The effectiveness of a lawn mower walking system is judged by its adaptability to specific mowing scenarios. Key considerations include the system's traction and stability on slopes, its maneuverability in tight spaces around landscaping features, and its ability to handle different grass types and moisture levels. For hilly or wet terrain, systems with enhanced differentials or sealed components prevent wheel slippage and maintain a consistent cut. On intricate residential properties with many obstacles, a zero-turn-radius capability, achieved through independent control of the drive wheels, becomes a highly valued feature of the lawn mower walking system. This allows for precise trimming without the need for additional passes, saving time and fuel. The selection process thus involves matching the technical specifications of the lawn mower walking system—such as its turning capability, ground clearance, and power delivery—to the specific contours and challenges of the intended work environment to ensure ideal performance and finish quality.

The modern lawn mower walking system is a sophisticated technical assembly where ergonomic science, commercial pragmatism, and functional versatility converge. Its evolution is driven by the need to support the operator's well-being, enhance business efficiency, and conquer diverse landscapes. As technology advances, particularly in the realm of electric propulsion and smart control integration, the lawn mower walking system will continue to be a foundational element that defines not just how a mower moves, but how effectively and sustainably a property can be maintained.

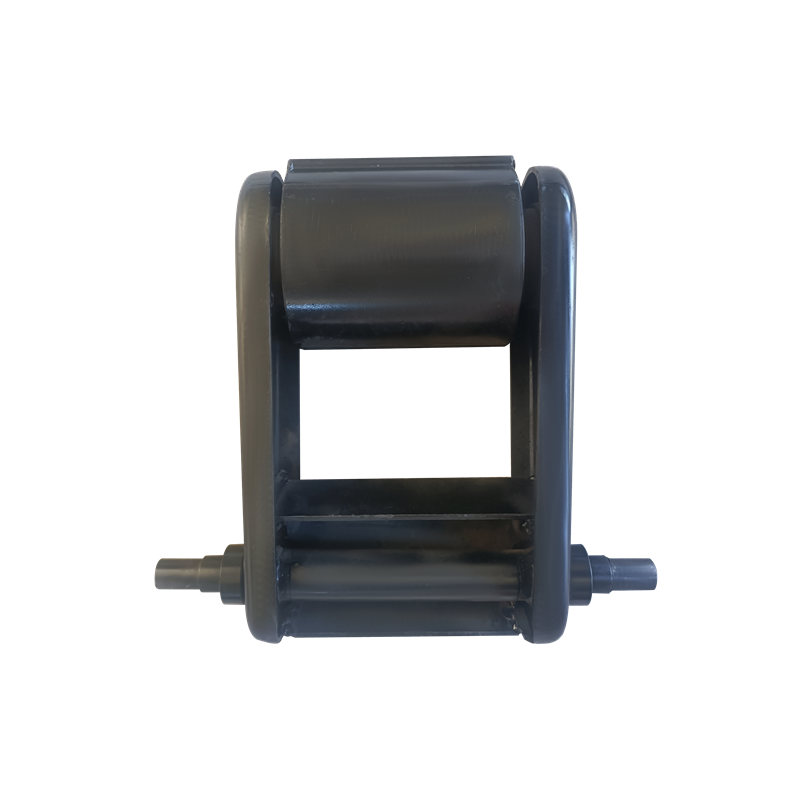

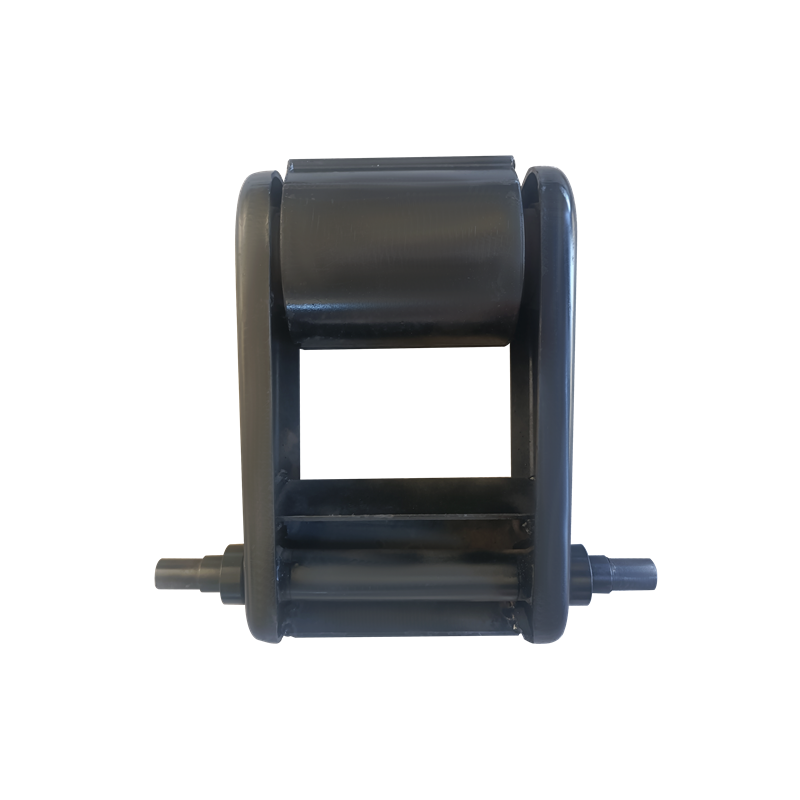

The Rocking Arm from LINHAI HAISDER MACHINERY CO.,LTD is a robust and precisely engineered component designed for agricultural and horticultural machinery. It serves as a critical linkage in equipment such as lawn mowers, hay tedders, or rakes, converting rotary motion into a controlled back-and-forth or rocking movement. Manufactured from high-strength steel or alloy with durable pivot points, it ensures reliable power transmission and operational stability under continuous heavy-duty use. Its design prioritizes smooth motion, wear resistance, and easy integration, making it an essential part for maintaining efficient and consistent performance in field and grounds maintenance equipment.

浙ICP备2022029871号

浙ICP备2022029871号